Are you looking for a used roll forming machine?

Why modernization is often the better choice

Many companies are specifically looking for a used roll forming machine in order to reduce investments or expand production capacities. In many cases, however, it is not worth buying a new machine – neither used nor new. Instead, modernizing an existing system is often the more economical and reliable option. PoVoTec shows you how you can bring your existing roll forming technology up to date – individually, efficiently and without unnecessary new investments.

Better than used: Modernize your existing roll forming system

The used market for roll forming machines looks attractive at first glance. Machines at reduced prices, often immediately available. In practice, however, it turns out that used systems do not always meet the specific requirements of a company. A lack of compatibility, high maintenance requirements and limited expansion options are just some of the factors that can lead to unexpected follow-up costs.

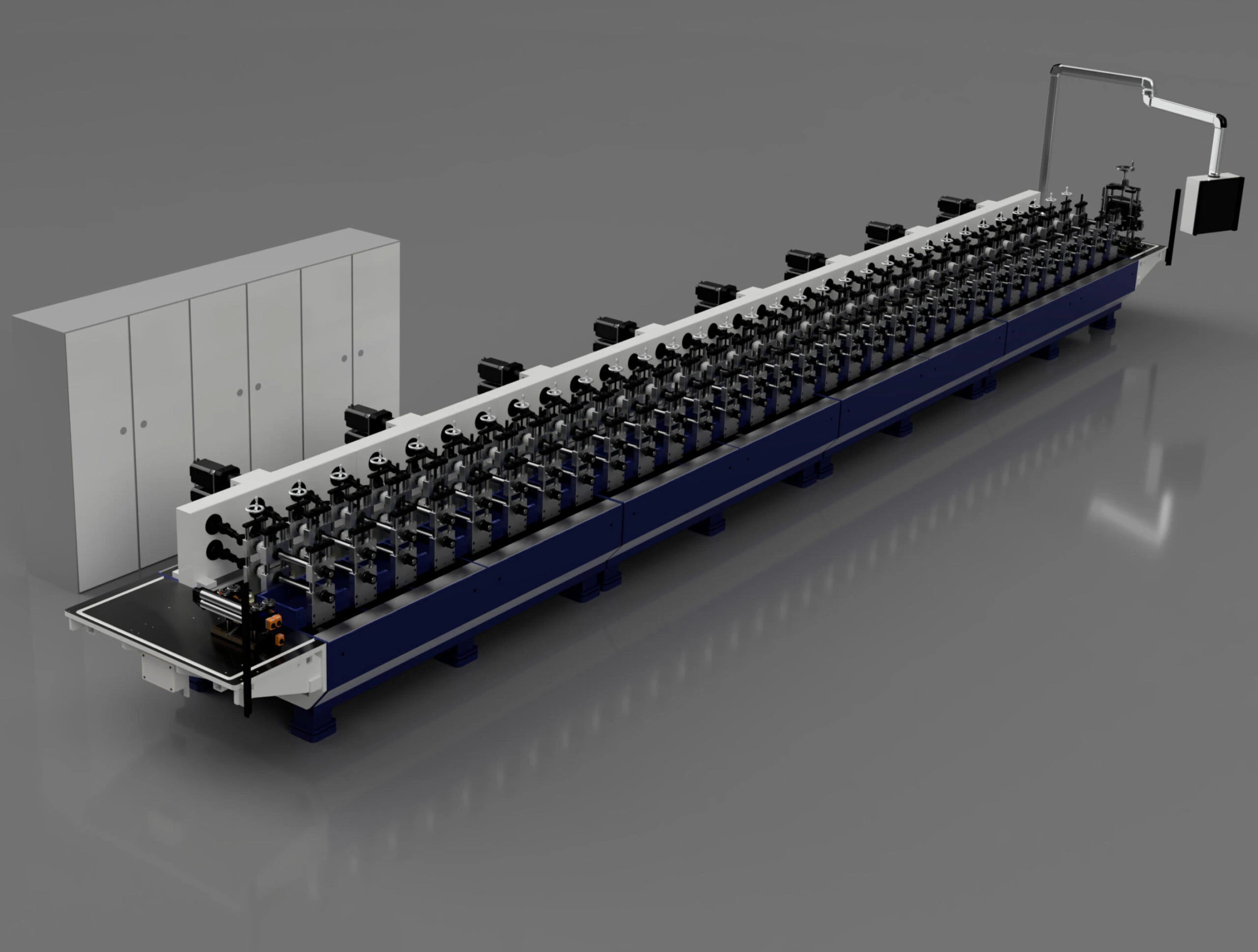

Instead of relying on a used roll forming machine, it is often worth taking a look at your own machinery. With targeted modernization measures, many systems can be brought up to the current technical level – precisely adapted to your production conditions. PoVoTec offers individual solutions for this, which are based on your existing equipment and focus on where optimization is necessary. This turns an existing line into an efficient system with improved output, less downtime and reduced operating costs.

Our solution: Increased efficiency through targeted retrofitting

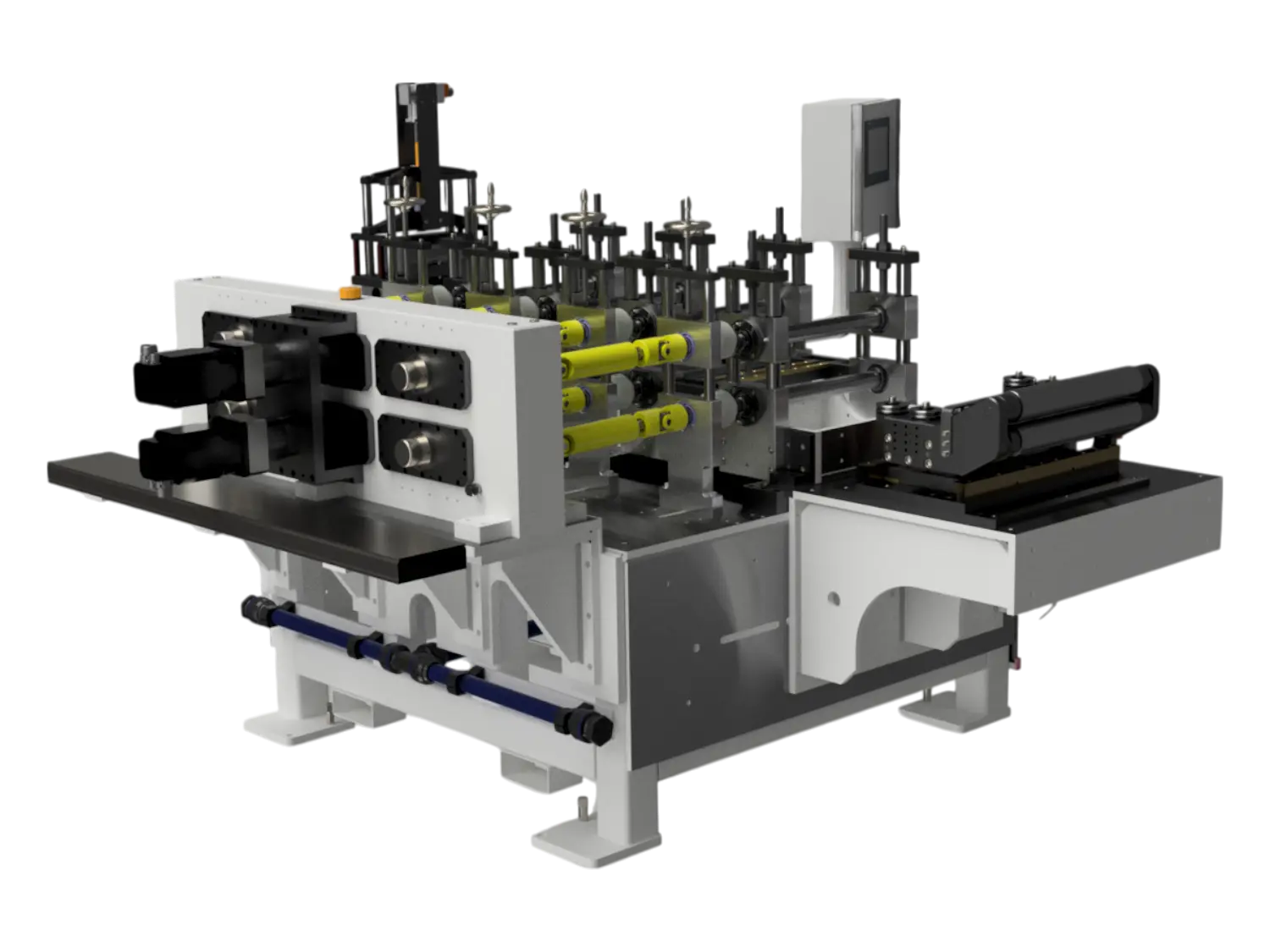

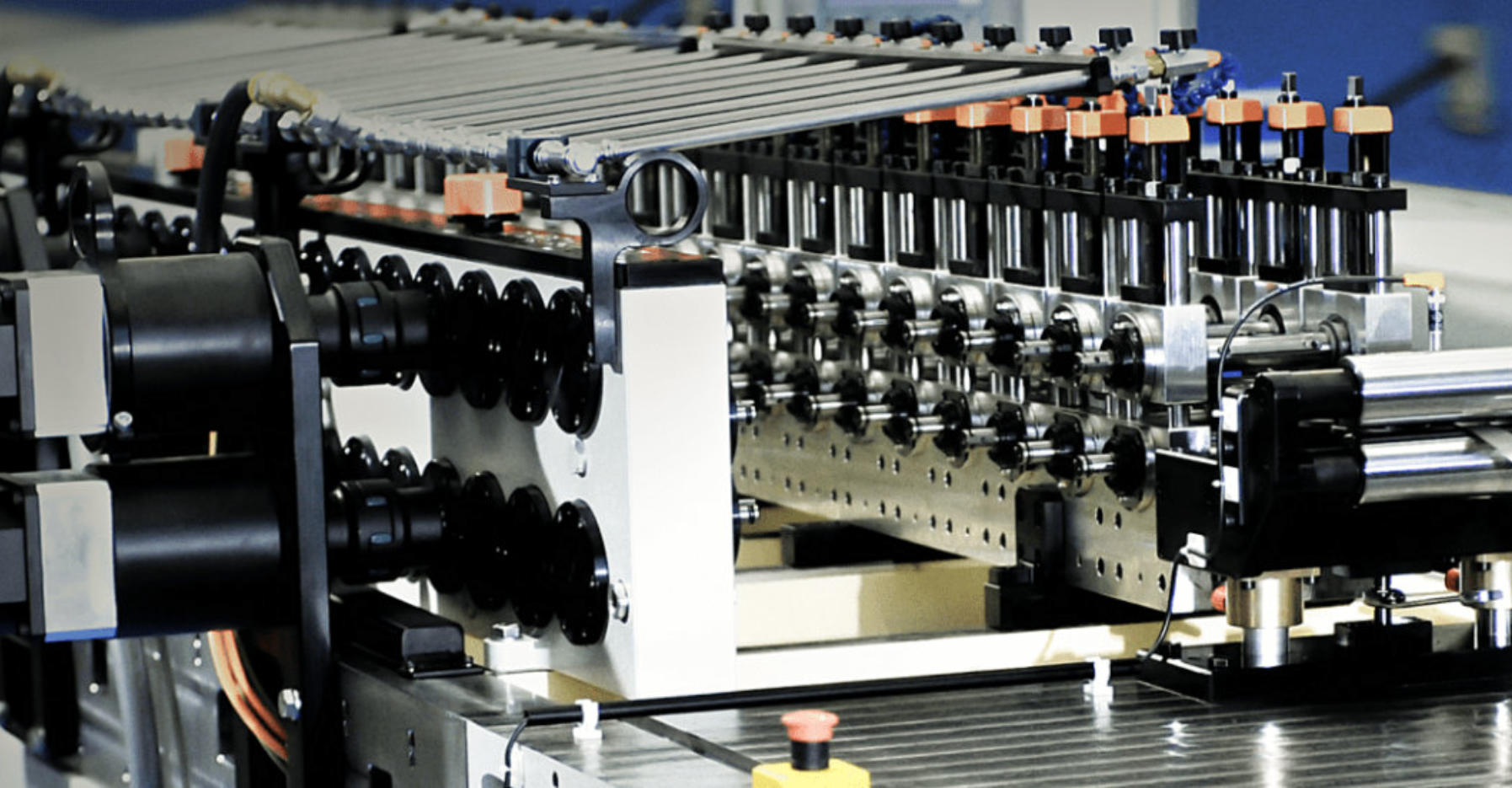

A central component of our modernization concepts is the specially developed quick-change cassette system from PoVoTec. It enables the tool-free replacement of complete roller groups within a few minutes – regardless of whether your system has 2 or 56 stations. The changeover takes place in just a few steps with just two crane operations and can also be carried out safely by less experienced employees.

The special feature: the existing roll stand is retained. Custom-made adapter plates create the connection between the existing technology and our system. Existing roll forming rolls can also continue to be used. This not only saves you time, but also investment costs, as no new roll sets need to be manufactured. The machine becomes more efficient, more flexible and still remains adapted to your product portfolio.

Modern control technology for maximum performance

Also for third-party systems: open system modernization

Modernization and retrofitting at PoVoTec is not limited to our own machines. We also regularly modernize systems from other manufacturers. The process begins with a precise inventory of your existing technology. Based on this data, we develop all the necessary components in our CAD system. Production takes place entirely at our factory in Eslohe.

The result is a tailor-made system that brings your third-party system up to the latest state of the art – without high downtimes and without unmanageable effort. Whether integrating the quick-change system or replacing outdated control systems: Even machines that have been in use for decades can be made fit for future requirements.

Your next step: Get non-binding advice now

If you are currently looking for a used roll forming system, it is worth comparing it with a tailor-made modernization of your existing system. PoVoTec offers you a comprehensive concept that is economical, sustainable and technically precisely tailored to your requirements. Instead of compromising on used machines, you can opt for a solution that makes your existing system more efficient.

Our range of services

- Concept development

- Feasibility check

- Planning

- Design / Construction

- Project planning

- Production / Assembly

- Commissioning / Acceptance

- CE-Documentation

- Employee training

- After-sales service

„Make your old system fit for the future! Contact us and we will be happy to advise you on the options for modernizing or retrofitting roll forming systems.”

Josef Kramer, Sales